In 2014, we launched the REP (Component Refurbishment in French) workshop, a project dedicated to repairing and reusing parts from used equipment.

This workshop restores spare parts that were initially set to be decommissioned, reintegrating them into the economic cycle after their airworthiness has been validated.

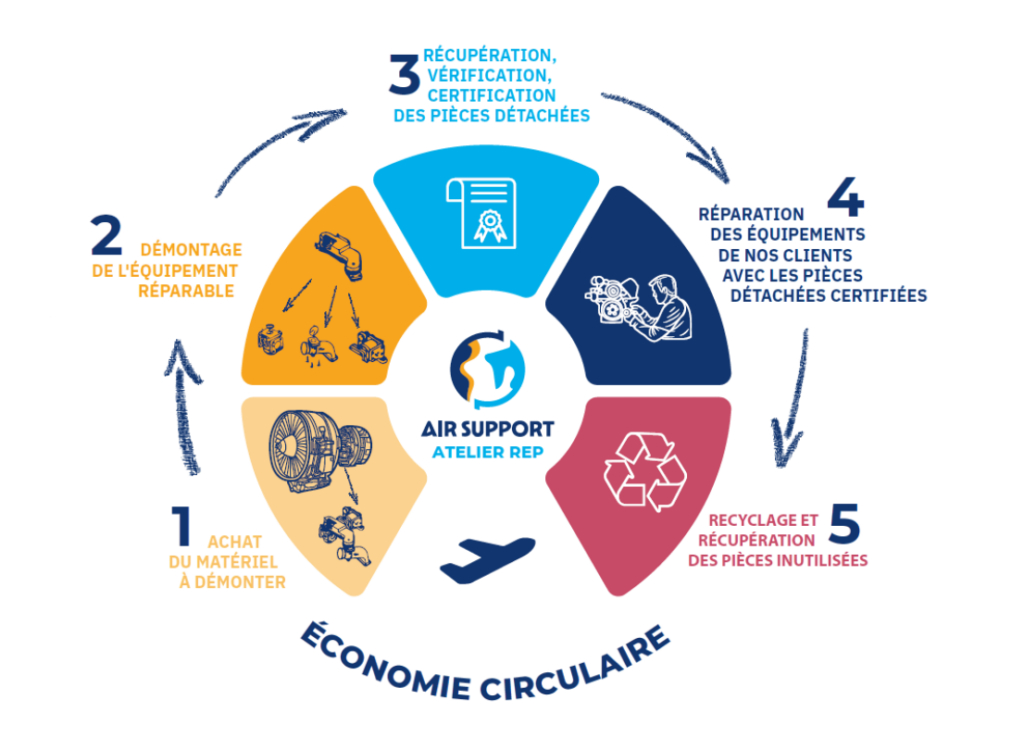

Our Approach to the Circular Economy

To give aircraft equipment a second life, we follow a process that combines recovery, repair, and certification of spare parts.

Each step is designed to optimize the reuse of components while ensuring their compliance with aerospace industry standards. Discover how it works through the visual below.

This process is part of our commitment to reducing our environmental footprint and contributing to more sustainable operations.

In 2023-2024, we refurbished over 11,000 spare parts, reducing our resource consumption (energy, raw materials, etc.) by a factor of 6.6. This allowed us to minimize waste production and reduce transport emissions.

A model with multiple benefits

By integrating the circular economy, we offer our clients cost-effective and responsible solutions:

- Cost reduction: certified refurbished parts, an affordable alternative.

- Optimized lead times: better availability of parts.

- Responsible commitment: a sustainable solution that helps reduce waste and CO₂ emissions.

This approach enables them to balance performance, cost savings, and environmental responsibility.

Our priority is to provide high-quality maintenance services, combining new parts and tailored repair solutions to meet the specific needs of our clients.

With the REP workshop, we offer responsible alternatives that complement our traditional services, providing cost-effective and eco-friendly solutions to extend the lifespan of equipment.